Our DeFever 41, Sanderling, has a teak mast (and boom) fastened in a tabernacle on the aft edge of the top deck. The mast with anchor light is 12 feet 9 inches in length and creates an air draft of 22 feet 3 inches above the waterline when the fuel and water tanks are about 1/2 full. The weight of the mast and boom together (135 pounds mid length) is such that it took two strong people to lower the mast and place it in the boom-crutch (doubles as a mast crutch when the mast is laid down). With the two of us cruising mostly by ourselves, it was a nearly impossible task to lower (and subsequently raise) the mast without asking for assistance. Our planned cruises into the Erie Canal and inland Canadian canals made it imperative that we be able to handle the task ourselves, and the only option was to create a block and tackle arrangement to provide the necessary mechanical advantage.

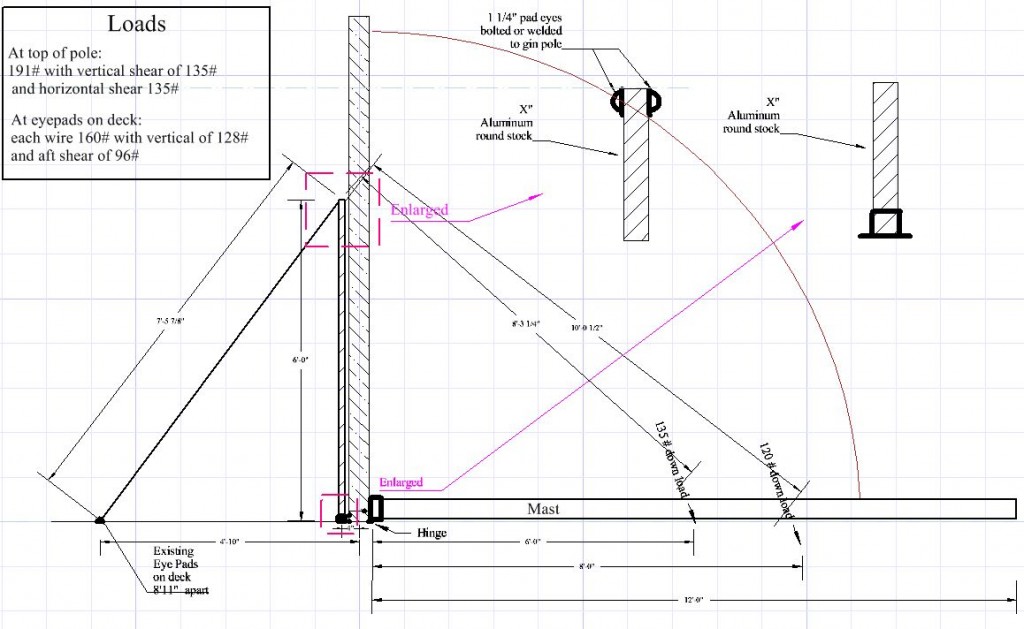

After consulting a number of other DeFever 41 owners, it became apparent that we had to come up with our own solution due to the full enclosure bimini around the upper deck, the weight of the mast, the location of a railing at the aft end of the upper deck, and my distrust of adding additional chain plates or pad-eye to bear the forces involved in lowering the mast with a block and tackle. The challenge was to create an attachment point for the block and tackle which would be as high as possible in order to minimize the loads involved as the mast went from a vertical to a horizontal position. The top of the bimini frame would not be anywhere near sufficient for the loads involved (and still have the bimini when we finished), and there was no other existing attachment point available. The only solution was to create an attachment point on a gin pole that would be up to the anticipated loads, removable, and stable.

Here’s a side-view drawing of what we came up with. The mast loads of 135 and 120 pounds were measured using a digital scales with the mast in the horizontal position.

There are two existing pad-eyes with turnbuckles located on either side of the upper deck behind the fixed bench seats; these are normally attachment points for the mast’s forward stays. (See photo #1)

These are used to provide support for wires to the top of the gin pole.

The interior dimensions of a preformed aluminum rectangular tube (provided by a friend) was almost exactly the dimension of a standard 2X4 wood stud, so instead of fabricating an aluminum gin pole, a 2X4 was used and 5 inches of one end were sanded down to fit the dimensions of the tube. A 5 inch section of the tube was cut from the stock and a plate welded across one end (a precaution that may not have been necessary). Two pad-eyes with rings were bolted to either side of the aluminum cap for attachment points. (See photo #2) Two lengths of galvanized wire-rope were cut to length and thimbles secured with wire clamps of appropriate size were added. The wire-ropes attach to the turnbuckles and to the gin pole with steel shackles.

For the block and tackle we used two 3-sheave Harken 2.25 inch triple blocks with becket sized for 7/16” inch braided line rigged to disadvantage. The fixed block is attached to the top of the gin pole with a steel shackle; the traveling block is attached to the mast about mid-point with a steel shackle and a length of 1/2” line wrapped around the mast above a standard cleat attached to the aft side of the mast. (See photo 3) The fall is lead to the boat deck and is controlled from there. This allows one-person operation due to the great mechanical advantage and also allows the mast to be guided from side to side to properly lay into the crutch.

The base of the gin pole is inserted into a shoe made of fiberglass/epoxy to fit the outside dimensions of the 2X4 with a 1/2” base to fit under the nut and stud and recessed in part which helps secure the mast in an upright position in the tabernacle. (See photo 4) The base is inserted under the nut once the mast is tilted backwards slightly. (See photo 5) When the shoe was being made, several layers of paper and plastic sheet were wrapped around the end of the the 2X4 before wrapping the fiberglass in order to ensure the gin pole would easily slide in and out of the shoe to make storage and replacement easier.

In use, the gin pole and supporting wires are assembled and the block-and-tackle tied to the mast; the forward mast stays are removed from the turnbuckle and the gin pole supporting wires are attached in their place; the base of the gin pole is located just forward of the mast tabernacle and the fixed block is attached. At this point the rig is fairly stable and will stand on its own. The pockets through which the forward stays pass in the bimini top are loosened to allow the stays to be pulled through (although they’re only pulled through when the mast is actually lowered). The nut on the tabernacle is removed and the mast tilted backward slightly with a slight amount of pull now transferred to the lowering rig. The gin pole shoe is inserted around the stud and the nut replaced and hand tightened onto the base of the shoe. The mast is then lowered a bit more until tension is placed on the rig; the operator then moves to the boat deck alongside the mast and coaxes the mast lower until the weight is held by the block-and-tackle and lowering is controlled by letting out the fall. The mast is guided into the crutch while the end of the boom lies on the deck. (See photos 6 & 7)

All materials were sized to exceed the anticipated loads by a factor of at least three.

The whole process takes about 10 minutes. Although raising and lowering the mast can be done by one person, a second person is extremely helpful in keeping everything steady and in pushing the mast backward to get the fall started. The whole rig stores in the lazarette.

Cruising the Erie Canal, the Canadian canals and through Lake Champlain into the Champlain Canal could not have been accomplished without the ability to raise and lower the mast easily. Removing the mast or permanently lowering it was not an option as we needed the ability to raise the mast once we were through the height-restricted areas in order to use the running and anchor lights and radar. This simple device made it all possible.

I am getting ready to lower my Defever 41 mast to replace the radar and all the lights. This post was extremely helpful. Thank you. My Defever has only one forward stay attached to the top of the bench seat by the helm. I hope it will be enough.

Glad to hear the article was helpful. It was the only way I could figure out how to lower the mast without taking several more crew aboard just for the process. You might consider how the forward stay is attached to the top of the bench seat and whether it is fully fastened. On our Sanderling, the top piece of teak trim (flat, the length of the seat) was simply screwed into the fiberglass frame and wouldn’t have been nearly enough to support the lateral and upward load, IMHO. You could add a couple of attachment points on either side of the upper deck just behind the seats to spread the load and with better/stronger attachment points.

Have you ever used your boom as a crane? Wouldn’t that put more stress on that point than lowering the mast?

Just a thought: If you’re only going to do it once to replace the radar and lights, why bother. OTOH, if you’re going to be cruising where the mast needs to be lowered and raised frequently, go for it. We came up with the solution because we were going to be cruising the Erie and Canadian Canals, where we wouldn’t necessarily have access to extra and stronger hands to help with the work. With our solution, my wife and I could do the work in short order without any additional assistance.

I do intend to do the loop and will want to be able to lower it as needed.